High-performance rare earth permanent magnet materials are widely used in low-carbon economic fields such as energy-saving and environmentally friendly manufacturing industries. As earth permanent magnet materials are widely used in low-carbon economic fields such as energy-saving and environmentally friendly manufacturing industries, countries around the world have invested heavily Low-carbon, energy-saving and environmentally friendly manufacturing industries, and promote green products. Countries have invested heavily in low-carbon, energy-saving and environmentally friendly manufacturing industries and promoted the consumption of green products. Emerging industries represented by new energy vehicles, wind power generation home-saving robots and smart manufacturing have developed rapidly. The demand for high-performance rare earth permanent magnet materials is expected to grow. Emerging industries are developing rapidly, and the demand for high-performance rare earth permanent magnet materials is expected to grow.

The permanent magnet material is mainly neodymium iron boron material among rare earth materials.

Permanent magnet materials are also called hard magnetic materials. They are characterized by high anisotropic field, high coercive force, large hysteresis loop area, and a large magnetizing field required for magnetization to saturation. It can still maintain a strong strength for a long time after the external magnetic field is removed. of magnetism.

The permanent magnet material works in deep magnetic saturation and the second quadrant demagnetization part of the hysteresis loop after magnetization. As an important basic magnetic functional material, it has a wide range of applications. my country's permanent magnet material industry plays an important role in the world. Not only are there many companies engaged in production and application, but research work is also in the ascendant.

Permanent magnet materials are mainly divided into rare earth permanent magnet materials, financial permanent magnet materials, composite permanent magnet materials and ferrite permanent magnet materials. Among them, neodymium iron boron under rare earth permanent magnet materials is a magnet product that is widely used and developing rapidly. It only took more than 20 years from the invention of NdFeB to its widespread application. Due to its high magnetic properties and easy processing, the price is not very high, so the application fields are expanding rapidly. At present, the magnetic energy product of commercialized NdFeB can reach 50MGOe, which is 10 times that of ferrite. NdFeB is also a powder metallurgy product, and its processing method is similar to that of samarium cobalt.

Since the advent of rare earth permanent magnet materials in the 1960s, their scientific research, production and application have been developing rapidly. According to the chronological order of their development and application, rare earth permanent magnet materials can be divided into four generations. Rare earth permanent magnet materials have now developed to the third generation of rare earth permanent magnets: neodymium iron. boron.

According to different manufacturing processes, NdFeB permanent magnet materials can be divided into three categories: sintering, bonding and hot pressing. Each has its own characteristics in performance and application. There is relatively little overlap in downstream application fields and they play functions with each other. complement rather than substitute or crowd out.

China takes advantage of rare earth NdFeB permanent magnet materials

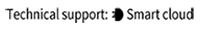

China is the largest rare earth producer. According to the total volume of rare earth mineral products in 2019, it accounted for 62.9%, followed by the United States and Australia, which accounted for 12.4% and 10% respectively.

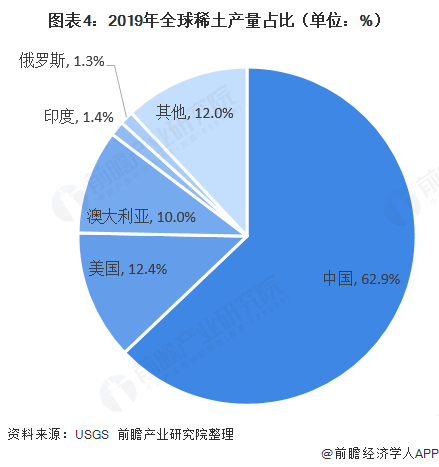

Thanks to rare earth reserves, my country has become the world's largest production base and export base of rare earth permanent magnet materials. According to statistics from the China Rare Earth Industry Association, my country produced 138,000 tons of NdFeB magnets in 2018, accounting for 87% of the global total and nearly 10 times that of Japan, which ranks second in global production.

The global application of rare earth NdFeB materials is relatively scattered

From the perspective of application fields, low-end NdFeB is mainly used in magnetic adsorption, magnetic separation, electric bicycles, luggage buckles, door buckles, toys and other fields, while high-performance NdFeB is mainly used in various fields of high-tech barriers. Magnets in various types of motors and speakers, including energy-saving motors, automobile motors, wind power generation, high-end audio and video equipment, elevator motors, etc.

China's rare earth NdFeB materials are rising steadily and are concentrated in Zhejiang

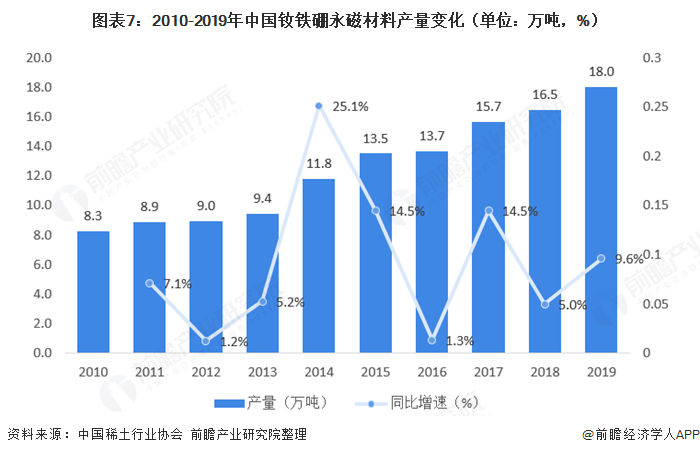

Since 2000, my country has become the world's largest producer of rare earth NdFeB permanent magnet materials. With the development of downstream applications, my country's output of NdFeB permanent magnet materials has maintained rapid growth. In the 10 years from 2010 to 2019, my country's NdFeB permanent magnet material output increased by 118%, with an average annual compound growth rate of 9.06%.

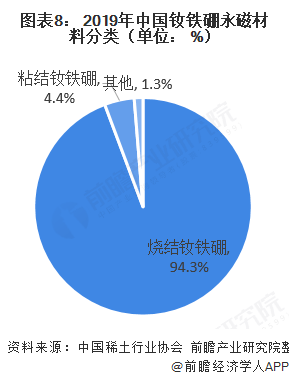

According to data from the China Rare Earth Industry Association in 2019, the output of sintered NdFeB blanks was 170,000 tons, accounting for 94.3% of the total NdFeB magnetic materials that year, bonded NdFeB accounted for 4.4%, and other total output accounted for only 1.3% . This data reflects that among NdFeB permanent magnet materials, sintered NdFeB magnets are currently the NdFeB permanent magnet materials with the largest output and the widest application range.

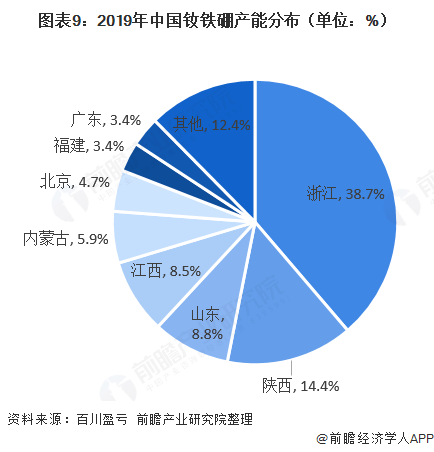

China's NdFeB production capacity is mainly concentrated in Zhejiang, Shanxi, Shandong, Inner Mongolia and other places. Among them, Zhejiang has the advantage of industrial concentration, with many enterprises and a comprehensively developed industrial chain. Its annual production capacity is 115,600 tons, accounting for 38.7% of the total domestic production capacity.

Production is expected to continue to rise

From the previous analysis, it can be seen that the global downstream consumption of NdFeB is distributed in the motor industry, buses and railways, intelligent robots, wind power generation and new energy vehicles. The growth rates of the above-mentioned industries in the next five years will all exceed 10%, which will lead to an increase in my country's NdFeB production. Although ferrite is the main component of permanent magnet materials at this stage, the price and functional advantages of rare earth NdFeB are impressive. It is preliminary and conservatively estimated that my country's NdFeB production will maintain a growth rate of 6% in the next five years and exceed 260,000 by 2025. ton.